Design of innovative buoyancy and connectivity accessories to improve the efficiency, reliability, and usability of Omiflo’s Phytofix™ wastewater treatment system for urban African communities.

MIT D-Lab class

Community partner

- Omiflo | Nairobi, Kenya

- Mshila Sio, Founder and Director

- Bradley Mbagaya, Mechanical Design Engineer

Student team

- Lilly Heilshorn (MechE BS, 2025). Fourth-year undergraduate student studying Mechanical Engineering with career interests in international development, human-centered design, and product design.

- Adrian Kombe (MDE, 2026).First-year master’s student at Harvard’s Design Engineering program with career interests in humanitarian engineering and electro-mechanical products

- Caroline Liu (MechE MS / MBA, 2026).First-year master’s student in the MIT LGO program with career interests in operations, manufacturing, and product design.

- Sehar Lohawala (MechE BS, 2025). Fourth-year undergraduate student studying Mechanical Engineering with career interests in product design, user-centered design, and architected materials.

Problem and context

In urban Africa, only 11% of the population has access to traditional sewer systems, forcing reliance on costly and unsustainable sewage alternatives. Omiflo’s Phytofix system offers an innovative, eco-friendly solution by using Typha plants, whose roots passively filter contaminants. However, the system faces critical challenges with buoyancy and connectivity that hinder its effectiveness and scalability.

The floating lattices supporting the Typha plants often sink due to material density and variable plant loads, causing the plants to submerge below the water surface. This reduces filtration efficiency and compromises the system's performance. Additionally, the joints connecting the lattices frequently fail, leading to misalignment. Non-coplanar lattices tilt or sink, disrupting the uniform distribution of plants and further impairing filtration.

Current workarounds, such as PVC flotation enclosures and string supports, are inadequate and expensive for long-term use. These temporary fixes lack durability, scalability, and ease of installation, limiting the Phytofix system's ability to meet the growing demand for reliable wastewater treatment across diverse environments. Urban African communities urgently need scalable and sustainable solutions that align with their requirements for low-cost, low-maintenance infrastructure. Enhancing the Phytofix system with reliable and user-friendly components addresses this need while fostering public health and environmental benefits.

Solution: accessory design

To address these challenges, the team developed two innovative accessories: the Flotation Cup and the X-Connect. Both were designed through iterative prototyping, rigorous testing, and validation to meet stringent performance, usability, and cost requirements.

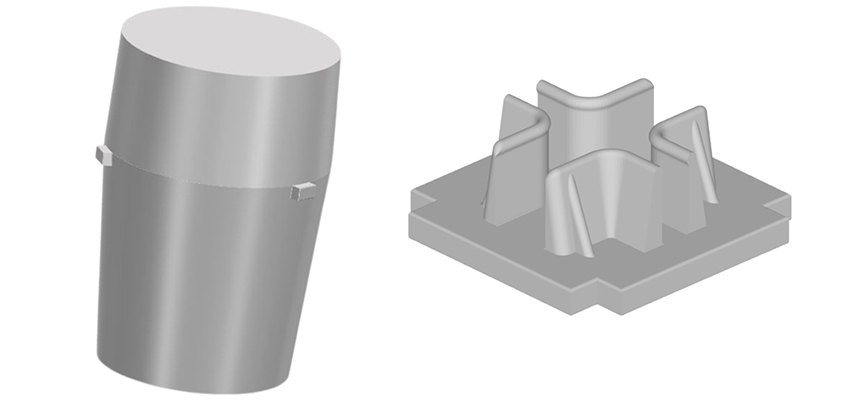

The Flotation Cup is a hollow, injection-molded accessory that increases buoyancy by up to 13.88%, ensuring the lattices maintain their optimal height relative to the water surface. This enables effective filtration by keeping the *Typha* plants in the correct position. The cup features a snap-fit mechanism with intuitive haptic feedback, making installation quick and simple for non-technical users.

The X-Connect is a bi-directional snap-fit connector that improves lattice connectivity, increasing the decoupling force by 300%. Its robust design includes angled stiffness ribs, ensuring long-term structural integrity under varying environmental conditions. These accessories resolve the Phytofix system’s operational challenges while improving scalability and ease of use.

Impact of accessories

The Flotation Cup and X-Connect have improved the performance and scalability of the Phytofix system. The Flotation Cup ensures consistent buoyancy, maximizing filtration efficiency by maintaining proper plant positioning. The X-Connect enhances structural reliability, preventing misalignment and ensuring a stable filtration system. Together, these improvements make the system more robust and adaptable.

Financially, these accessories deliver substantial savings. By replacing the current workarounds, material costs are reduced by 35%. Installation times have decreased by 65–75%, enabling faster deployment and cutting labor costs. These efficiencies are projected to save Omiflo approximately $35,000 in operational expenses in 2025 alone. Additionally, the improved reliability supports the use of heavier, more efficient plant species, further enhancing filtration potential and expanding the system’s applicability to new markets and regions.

Hand-off and next steps

The team delivered a comprehensive package to Omiflo to facilitate the seamless integration of these accessories. This included CAD designs, cost analyses, and installation guidelines for the Flotation Cup and X-Connect. Injection molding using polypropylene copolymer was recommended as the manufacturing method, chosen for its cost-efficiency and durability in wastewater environments.

To implement the redesigned components, the next steps involve creating injection molds, conducting field tests to validate durability and fit, and piloting the accessories in a customer site installation. Establishing a quality management system will ensure consistent production, particularly for waterproofing and part retention. By completing these steps, Omiflo will be ready to deploy the enhanced Phytofix system at scale, delivering affordable and reliable wastewater treatment to urban African communities.

Contact

Macauley Kenney, D-Lab: Design for Scale Instructor

Caroline Liu, student team member

Sehar Lohawala, student team member

Lilly Heilshorn, student team member